Clean Water and Sanitation

B.S. Abdur Rahman Crescent Institute of Science and Technology takes sufficient measures to treat the wastewater generated within the premises and it ensures that the treated water is reused within the campus. The Institute has established suitable and sustainable sewage treatment plants with the design features to completely treat the wastewater generated in the Institute. The details of the treatment plant and the process of wastewater management are given below

2 nos. of Sewage treatment plants of 250KLD capacity are installed in the campus

| Location | Capacity | Remarks |

|---|---|---|

| College campus | 250KLD | Commissioned in 2003 as a 150KLd plant. Revamped and capacity increased to 250KLD in 2015 |

| Men’s Hostel | 250KLD | Commissioned in 2014 |

- The sewage generated in the Institute is generally characterized by the presence of organic, inorganic and suspended solids.

- The chain of treatment is aimed to remove such pollutants from the wastewater so that it can be effectively reused

- The treatment system consists of preliminary treatment system followed by the primary and secondary treatment process

- Bar Screens are used in the treatment plant to remove materials like plastics and other floating objects

- The grit chambers are used to remove sand and silts from the wastewater

- The primary sedimentation tank helps in the removal of the suspended solids

- The biological treatment system is the secondary treatment process used in the removal of organics from the wastewater

- The suspended solids are removed using the primary sedimentation tank and after this the wastewater is subjected to biological treatment to remove the organic content from the waste.

- The secondary treatment process is incorporated with ECO-BIO BLOCK so as to increase the efficiency of the treatment system

- The Eco-Bio Bricks helps in the attachment of bacteria in the treatment system and helps in the better removal of organic content from the wastewater

- This attached system will also help the treatment system to handle shock loadings if there is an increase in the organic loading rate in the biological treatment system

- The sewage treatment plant is working on the principle of attached growth aerobic system (Eco-Bio Block) followed by sand filter and carbon filter

- The carbon and sand filter ensures that any amount of organics that is left in the wastewater is suitably adsorbed from the wastewater and it is stored in the collection tank

- The entire Sewage Treatment Plant is periodically subjected to maintenance regularly

- The working of all the pumps and valves are checked periodically to ensure the smooth functioning of the sewage treatment plant

- The treated water is used for landscaping and toilet flushing purpose

- This helps the university to reduce its dependency of fresh water from wells for gardening

- The physical, chemical and biological characteristics of the treated water are tested to ensure the efficiency of the treatment systems

- Some of the important parameters checked include pH, solids, Chemical oxygen demand, Biochemical oxygen demand, Nitrates, chlorides etc.

- The treated wastewater is checked periodically to ensure its quality so that it can be effectively reused for gardening and as well for the toilet flushing

The Institute through its continous treatment and monitoring, could achieve 90% of water reutilization

| S.No | Location | Total waste water collected | Water recycled | % of water reutilized |

|---|---|---|---|---|

| 1 | College campus | 250 KL | 220KL | 90 |

| 2 | Men’s Hostel | 250 KL | 220KL | 90 |

The Institute has also established MIRA CARBON SEWAGE TREATMENT PLANT of 2m3 capacity and VERMI FILTRATION TREATMENT UNIT in association with M/S.Kanyo Group of Companies to treat the wastewater generated from the Institute.

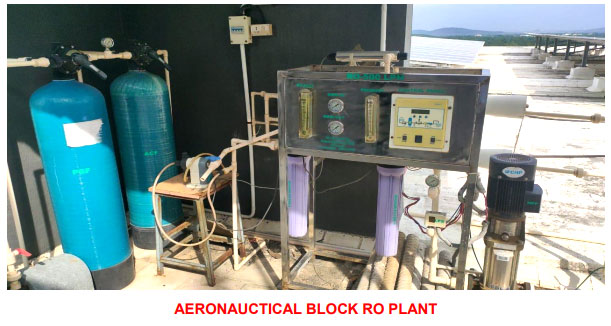

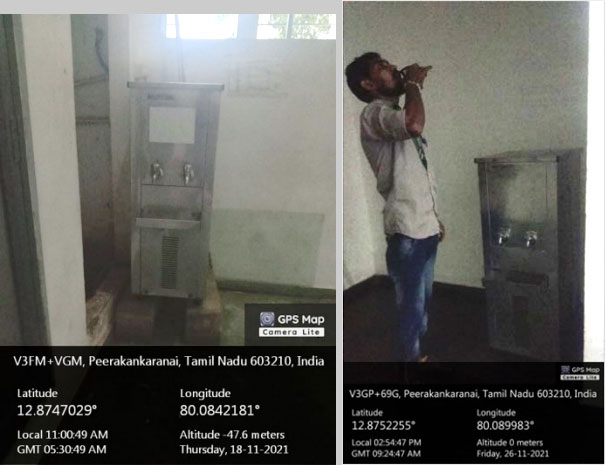

BSA Crescent Institute of Science and Technology has Reverse Osmosis (RO) Plant to provide drinking water to the college and hostel. The entire college campus is facilitated with pure Reverse Osmosis (RO) drinking water with water coolers in every block to cater to the need of pure and safe drinking water to all. The Institute has RO systems with a processing capacity of 44,500 liters / day installed in the campus and water dispensers are available in each floor in every building. The water treatment plants provide safe drinking water at every tap on the campus. A high level of maintenance frequent inspection and regular testing ensure the quality of the water. Water treatment plant with reverse osmosis technology is available to provide quality drinking water.

| S.No | Location | Capacity Liters/Hr | Working Hours Per day | Qty. of Treated Water in liters |

|---|---|---|---|---|

| 1 | University Main Plant-Near to Main block | 1500 | 6 | 9000 |

| 3 | Ladies Hostel New block Terrace | 500 | 5 | 2500 |

| 4 | Men’s Hostel Dining Hall | 2000 | 4 | 8000 |

| 5 | Men’s Hostel Service block | 2000 | 5 | 10000 |

| 6 | Aeronautical Block terrace | 500 | 2 | 1000 |

| 7 | Life Sciences block terrace | 500 | 2 | 1000 |

| 8 | New architecture terrace | 2000 | 4 | 8000 |

| Total treated Water | 10000 | 44500 | ||

B.S.Abdur Rahman Crescent Institute of Science and Technology provides free drinking water for staff, students and visitors. It also ensures that the drinking water is of good quality and meet the standards. For this purpose the Institute has established water treatment plant in the campus. The details are given below.

There are 5 Water Treatment plants installed at various places in the campus to treat the water before use in toilets, quarters, Men’s Hostel & Ladies hostel.

The capacity and quantity of water treated by each plant is tabled below.

| S.NO | LOCATION | CAPACITY | WORKING HOURS | REMARKS |

|---|---|---|---|---|

| 1 | New staff Quarters | 5m3/hr | 10 | Commissioned in Apr -2016 |

| 2 | New ladies hostel | 5m3/hr | 12 | Commissioned in Aug -2016 |

| 3 | Men’s hostel service block | 10m3/hr | 18 | Commissioned in Aug -2016 |

| 4 | VC Villa | 1m3/hr | 4 | Commissioned in Jan -2017 |

| 5 | Life Science block | 5m3/hr | 8 | Commissioned in Aug -2017 |

| Total Treated Water | 3,35,000Liters per day | |||

WATER TREATMENT PLANT

The water consumption details are given below

| Sl. No | Water Consumption / Day | Occupancy in Nos | consumption/day in liters |

|---|---|---|---|

| Occupants | |||

| 1 | College Student day scholars 45 lit/day @ 70% usage | 3700 | 116550 |

| 2 | Ladies Hostel 125 lit/day | 470 | 58750 |

| 3 | Men’s Hostel 125 lit/day | 1400 | 175000 |

| 4 | Miscellaneous (1)College/ staff 45 lit/day | 400 | 18000 |

| (2)Estate office staff 30lit/day | 350 | 10500 | |

| (3) General workers | 280 | 8400 | |

| (4) Kitchen and canteen | 50 | 10000 | |

| 5 | Quarters 125lit/day | 400 | 50000 |

| 7050 | 447200 | ||

| 6 | Floating @ 5% | 7403 | 10575 |

| Total water consumption/day in liters | 4,57,775 | ||

| Avg water consumption per capita/day | 62 |

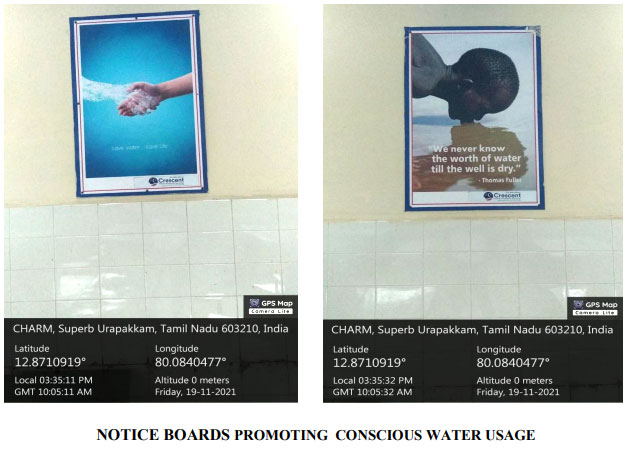

The Institute has adopted different measures to promote the conscious water usage on campus and in the wider community.

The Institute has installed various Notice boards such as “ Save water” and various other messages promoting the conscious water usage. These boards are placed across canteen, Mens hostel and in several other locations in the campus. This will create awareness and reduce the water consumption while washing hands etc among students and various other stakeholders

The Institute has given due consideration in promoting initiatives for saving energy and reducing water usage in buildings by emplyoying sensors. In order to minimize water usage and also to avoid the unnessary wasteage of water, automatic waterlevel controller and automatic flush controller with sensors are being installed in the campus

Our Institution is trying to implement smart water management system in the campus. Towards this, a proposal has been received from WEGoT Utility Solutions- Smart Water Management. This project puts forward an IoT-based solution for collecting water level from the tanks using sensors, transmitting it to a centralized server, visualizing the data through a web interface. The automated system helps the maintenance team to monitor the amount of water consumed in various buildings using the consumption details provided by the system.